Charter 400 Project - Beginning to Enamel the Plaques

Posted on

Beginning to Enamel the Plaques

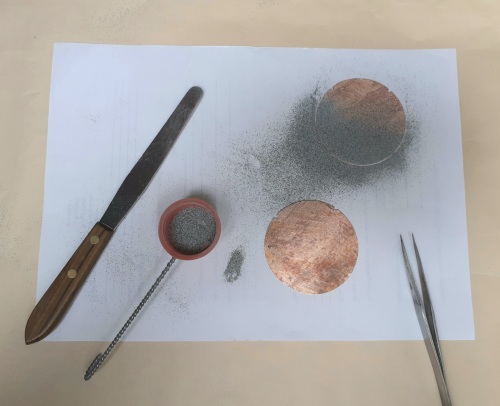

Now I can begin to enamel the copper 'blanks' using specially produced glass powders.

Both sides of the shapes need a covering of enamel. This is because the copper becomes soft when it is heated and could be bent, breaking the enamel. The the only way to make it firm again is to have each side coated.

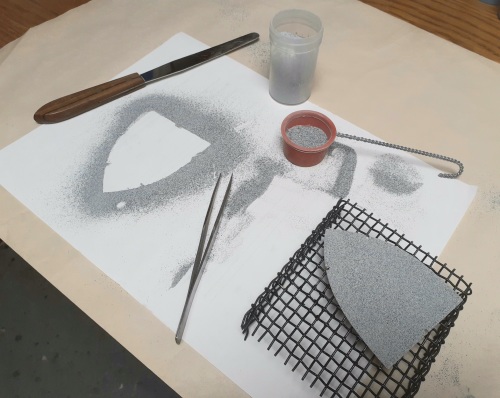

A layer of this powder (made up of mixed colours) is dusted onto the reverse of each using a small fine mesh sieve.

The copper shape goes into a hot kiln (around 800 degrees Centigrade) supported on a stainless steel mesh stand. After a short time the enamel powder will have melted and adhered to the copper and can be taken out of the kiln.

Once it is cool enough to handle another layer of enamel is applied over the first, and the firing is repeated. The result will be better if layers are built up rather than trying to create one thick layer.

Two layers of the backing ‘counter enamel’ is usually sufficient.

In the next post, enamelling the front of the plaques.

Add a comment: