Charter 400 Project - Beginning to make the Plaques.

Posted on

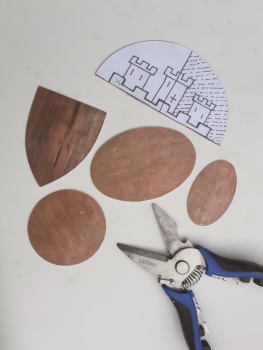

Beginning to make the Enamel Plaques

The shapes for the plaques known as blanks are cut out of recycled copper.

- Unlike new copper sheet, recycled copper needs to be cleaned before it is enamelled otherwise the enamels might not adhere properly.

- The first step is to heat the blank in the enamelling kiln until it glows a dull red. This process is called annealing and softens the copper. During heating a film of black oxide known as fire scale forms over the blank. This and any other discolouration can partly be removed by plunging the copper shape into cold water.

- To completely clean the copper it is placed in a warm acid solution.

- Once it is clean, it is rinsed and dried then gently hammered flat between two steel plates.

Add a comment: